GRUNDOMAT soil displacement technique

The pneumatically driven hammers work according to the soil displacement method. When moving forward the spoil is displaced into the surrounding soil. That way a channel is produced into which socketless short or long pipes up to OD 160 made of plastic (PE, PVC or PE-X) or cables can be pulled in. Depending on the type of soil lengths up to 15 m can either be pulled in successively or later. A compressor with 6 - 7 bar operating pressure is required for this. Exact alignment of the machine towards the target is necessary for a high target accuracy. To achieve this, the decisive factor is the 2-stroke principle.

The pneumatically driven hammers work according to the soil displacement method. When moving forward the spoil is displaced into the surrounding soil. That way a channel is produced into which socketless short or long pipes up to OD 160 made of plastic (PE, PVC or PE-X) or cables can be pulled in. Depending on the type of soil lengths up to 15 m can either be pulled in successively or later. A compressor with 6 - 7 bar operating pressure is required for this. Exact alignment of the machine towards the target is necessary for a high target accuracy. To achieve this, the decisive factor is the 2-stroke principle.

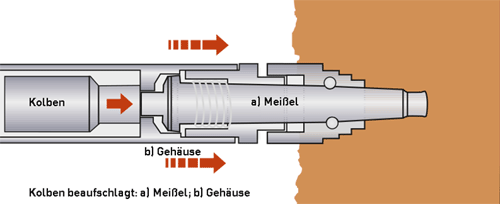

THE 2-STROKE PRINCIPLE

With the proven 2-stroke principle the piston initially strikes the multi-cutter cone which advances in order to produce the bore hole and to destroy any possible obstacles. The casing is imposed with the second strike and pulled in with the pipes attached. Peak resistance and casing friction are separated and alternately easier to overcome. This makes the GRUNDOMAT work dead on target even in stony grounds.

GRUNDOMATN: Versatilely applicable

-

Undercrossings

Beside road crossings, property service connections are everyday tasks for the GRUNDOMATN hammer. -

Pipe ramming from MODEL 130

GRUNDOMATN can also be used for ramming in steel pipes by attaching a special ram cone to the head of the machine. -

Pipe bursting from MODEL 95

Modified soil displacement hammers are also applicable for pipe renewal using the pipe bursting method. -

Piling

The vertical use, e.g. piling for laying foundations, is an interesting application as well.

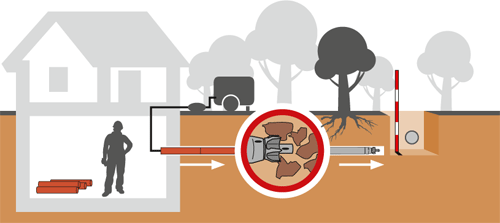

Property service connections - directly from inside the building

Bei Hausanschlüssen für Gas, Wasser, Abwasser, Strom, Breitbandverkabelung (FTTB) können Erdraketen auch direkt aus dem Haus starten. Ein Kopfloch vor der Hausmauer ist nicht mehr erforderlich. Das macht den Einsatz noch wirtschaftlicher, und der Vorgarten wird geschont.

- for FTTB, gas, water and power property service connections

- within minimal set-up time the soil displacement hammer can be started from inside the building after the core bore

- A wall duct is set up on the inside and seals off the basement wall from the outside and inside.

- The Grundomat equiment fits into a small transporter van

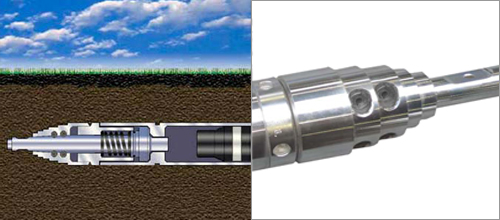

GRUNDOMATN with crowned head

The crowned head develops ist full efficiency in non-cohesive, stony soils. It expands the bore directly to the full bore diamteter. The sharp cutting crowns force their way into larger stones to fragment them. Due to the small contact surface of the cutting crowns, the highest possible degree of efficiency is achieved with the same amount of striking energy. The spoils are pushed through the openings between the cutting crowns and displaced to the rear. Then the penetration process starts.

GRUNDOMATN with stepped head

The proven stepped ghead is universally applicable in any type of soil. At first the chisel tip moves forward “opening” the soil. Then the bore head penetrates the soil step by step at high precision. The displacement process runs off gradually thus guaranteeing high running stability. But nort every type of soil is suitable for the stepped head or the crowned head vice versa. In these cases the bore head can be exchanged without difficulty.

-

The "head work" is carried out in 4 instead of 3 working steps;

Pre-stroke • Pulverizing • Relocation • Penetration

- Connection hose

- Direct installation for PE and PVC pipes

- Ground stake

- Sleeve pipe with steel rope insulator

- Lubricator

- Starting cradle for vertical and lateral alignment

- Telescopic aiming frame GRUNDOSCOPE

- The GRUNDOMATN generation is even more service friendly. Maintenance works such as replacing of a seal ring or attaching a pull sleeve for direct pipe pulling, can be carried out directly on site. There is no need to glue in any threaded connections of machine parts. The trick: a tensioning device spreads the thread like a dowel and fixes the casing end inside the casing.

GRUNDOMATN Technical data

| GRUNDOMAT Type | Bore Dimater Ø (mm) |

Length (mm) | Weight (kg) | Air consumption (m³) | # of strikes 1. gear (min-3) |

# of strikes 2. gear (min-3) |

Max Pipe OD max AØ (mm) |

|---|---|---|---|---|---|---|---|

| 45N (2-gear) | 45 | 997 | 9 | 0,35 | 530 | 635 | 40 |

| 55N (2-gear) | 55 | 1131 | 15 | 0,5 | 470 | 570 | 45 |

| 65N (2-gear) | 65 | 1290 | 24 | 0,8 | 460 | 585 | 50 |

| 75N (2-gear) | 75 | 1399 | 33 | 0,9 | 395 | 480 | 65 |

| 85N (2-gear) | 85 | 1528 | 46 | 1,0 | 360 | 440 | 75 |

| 95N (2-gear) | 95 | 1762 | 65 | 1,4 | 320 | 415 | 85 |

| 110N (2-gear) | 110 | 1700 | 96 | 1,7 | 350 | 410 | 90 |

| 130N (2-gear) | 130 | 1802 | 117 | 3,0 | 370 | 435 | 110 |

| 130N (Servo) | 130 | 1802 | 117 | 3,0 | 340 | - | 110 |

| 145N (Servo) | 145 | 2033 | 168 | 3,4 | 310 | - | 125 |

| 180N (Servo) | 180 | 2280 | 260 | 4,5 | 280 | - | 160 |

| Short versions | |||||||

| 45NK (1-gear) | 45 | 875 | 8 | 0,35 | 530 | - | 40 |

| 65NK (1-gear) | 65 | 933 | 16 | 0,8 | 600 | - | 50 |

| 75NK (1-gear) | 75 | 1100 | 24 | 0,9 | 496 | - | 63 |

| 95NK (1-gear) | 95 | 1393 | 50 | 1,4 | 390 | - | 85 |